ABRASION RESISTANT 450 PLATES

What is ABRASION RESISTANT 450 Steel Plates ?

What we offer AR (ABRASION RESISTANT) 450 Steel Plates

Salient Characteristics of our ABRASION RESISTANT 450 Wear Plates

AR ABREX 450 Plate Grades and Specification

ABRASION RESISTANT 450 Plate Properties

ROCKSTAR 450 Plate Application Industries

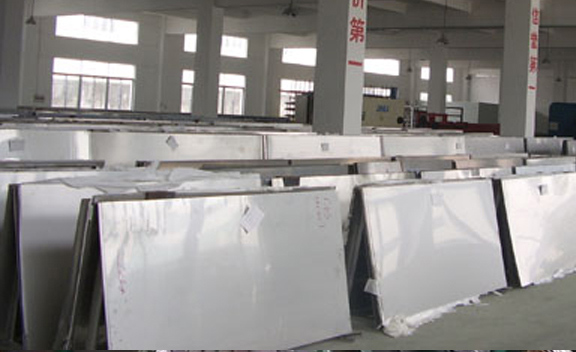

SSSM Group is a mega stockholder of an extensive range of first – in – class wear resistant and abrasion resistant Steel plates. We are suppliers of AR (ABRASION RESISTANT) 450, the Steel plate having supremacy regarding brute strength, resistance to any contusions and can withstand the ravages of time.

Abrasion Resistant 450 Plate, ABREX 450, JFE 500 Plates, QUARD 450 Plates, AR 450 Plates, SUMIHARD K-450 Plates, HARDEN PLATE, 500 HARDNESS, XAR 450 Sheets Dealer, DILLIDUR 450V Plates, ABRAZO 450 Plates Supplier in India.

ROCKHARD 450, AR Abrex 450 Plate, Abrex 450 Plates Stockholder, NICRODUR 450 Plate, BRINAR 450 Plate Distributor, FORA 450 Plates Exporter, 450 BHN HARDNESS PLATE, 450 HARDNESS, SWEBOR 450 Plate Stockist in Mumbai, India.

What is ABRASION RESISTANT 450 Steel Plate ?

ABRASION RESISTANT Steel is a wear and tear Steel. Our AR 450 Steel plates are extremely tight, manufactured in style to sustain substantial rigour. A unique combination of strength and durability, we offer you our AR 450 Steel plates, commonly known as ABREX 450 and SWEBOR 450, specially designed as per your industry demands.

AR 450 also known as Abrasion Resistant 450, ABREX 450 and XAR 450, comes in different grades; its size is adjustable to a customised dimension, making it extremely useful.

Salient Characteristics of our ABRASION RESISTANT 450 Wear Plates :

1. Extended wear life

Our AR 450 Steel plates not only provide defence against dents and damages but also expand the lifespan of the structure build using it. With an extra 50 Brinell of added hardness, its capacity to deter crack and evenly slice up the collision impact from a stony object raises its wear life by 50% than ordinary Steel. Eventually the overall uptime i.e. the operation period of a machine built with FORA 450 Steel plates increases as a whole.

2. Reduced downtime for maintenance

As DUROSTAT 450 and DILLIDUR 450V wear plates, types of AR 450 Steel plates, are boosted with added toughness against absolute wear, they need minimal down – time for maintenance. Sequentially it proceeds in less breakdown of machinery; smooth functioning of all parts and an excessive production.

3. Small lifespan cost

Abrasion Resistant wear plates like NICRODUR 450, ABRAZO 450 and BRINAR 450 are rugged, grain – refined and have high impact properties; they prolong the life cycle of an assembly twice and scarcely require upkeep. All this sums up to warding off the expenses on repair and inspection of these wear plates, saving capital and labour as well.

4. More payload and Profitability

A sole factor of AR 450 Steel plates, Rockstar 450, HBW 450 and HB 450 is that they are drastically light – weighted, allowing to contain extra load capacity. For e.g. a truck built from XAR 450 or AR 450 Steel plates will derive additional payload, with an increased profit arising from increased ferries.

5. High weldability and fabrication friendly

The chief advantage of CREUSABRO 8000, JFE EH400 LE and 450 BHN wear plates is their ability to be bent and welded with great comfort. Though they are immensely durable and hard, they are flexible too, to be bent and cut into several dimensions and shapes. They are welded with many methods, permitting fabrication to add value to the finished product.

ABRASION RESISTANT 450 STEEL PLATES

We offer the most superior quality, leading – edge wear resistant AR 450 Steel plate, with variants like SUMIHARD 450, ROCKSTAR 450 and Abrex 450. We offer the most superior quality, leading – edge wear resistant AR 450 Steel plate, with variants like SUMIHARD 450, ROCKSTAR 450 and Abrex 450.

ABRASION RESISTANT 450 Plate Specification :

Thickness : 5mm to 150mm

Width : 1,500mm to 2,500mm

Length : 6,000mm to 12,000mm

Heat Treatment : N, Q+T

Surface Paint : EP, PE, HDP, SMP, PVDF

Material : ABREX 450 Plate, Abrasion Resistant 450 Plate, SUMIHARD k450 Steel Plate, DILLIDUR 450V Steel Plate, Essar Rockstar 450 Abrasion Resistant Steel Plates.

The cold bending process produces Abrasion Resistant 450 Steel plates like JFE EH400 and ABRAZO 450, having a nominal hardness of 450 HBW, facilitating their use in many applications.

1) Recycling process comprises of segregation of waste materials, demanding the recycling equipment to be very tough. Our RAMOR 450, SAILMA 450 and CREUSABRO 450 wear resistant Steel plates are perfect for bulldozer blades, to stay productive in the recycling business.

2) Machines like trucks, bulldozers, crawler excavators, motor graders, etc. are commonly used in road – building. While constructing a road, these appliances face sliding wear and impact wear, requiring them to be made of Abrasion Resistant Steel Plates like ABREX 450 and SUMIHARD 450 as they are accustomed to bear the abuse from gravel and rocks.

3) Container trucks, cement mixers, mobile cranes, log carriers, etc. are classified as heavy duty trucks, carrying massive loads. AR 450 Steel plates equip trucks with lightly – weighing bodies to carry extra cargo and ferry frequently.

4) Equipment and assemblies in industries like the refinery, aerospace, chemical, etc. use AR 450 materials, as they are more reliable, sturdy, have unique uptime and wear performance.

Properties of Abrasion Resistant 450 Plates

- Equivalent CET(CEV)

- CHEMICAL COMPOSITION

- Mechanical Properties

| Thickness mm | -5 | 5 – (10) | 10 – (20) | 20 – (40) | 40 – 80 | (80) – 130 |

| CET (CEV) Max | 0.37 (0.48) | 0.38 (0.49) | 0.39 (0.52) | 0.41 (0.60) | 0.43 (0.74) | 0.41 (0.67) |

| CET (CEV) Typical | 0.29 (0.39) | 0.33 (0.45) | 0.36 (0.48) | 0.38(0.56) | 0.38 (0.61) | 0.39 (0.64) |

| C *) | Si *) | Mn *) | P | S | Cr *) | Ni *) | Mo *) | B *) |

| Max % | Max % | Max % | Max % | Max % | Max % | Max % | Max % | Max % |

| 0.26 | 0.7 | 1.6 | 0.025 | 0.01 | 1040 | 1050 | 0.6 | 0.005 |

| Thickness | Hardness HBW | Typical yield strength MPa, |

| mm | min – max 1) | not guaranteed |

| 3 – 80 | 425 – 475 | 1100 – 1300 |

| (80) – 100 | 410 – 475 | 1050 – 1300 |

| (100) – 130 | 390 – 475 | 1000 – 1300 |

Brinell hardness, HBW, according to EN ISO 6506-1, on a milled surface 0.5 – 3 mm below surface. At least one test specimen per heat and 40 tons. The nominal material thickness will not deviate more than ± 15 mm from that of the test specimen.

Impact Properties of Abrasion Resistant ABREX 450 Plates

| Impact properties | 450 BHN | 450BHN Tuf Transverse test, guaranteed | Longitudinal test, typical |

| Impact energy (J) | – | 27 J/-20degree c | 50J/-40degree c |

| Charpy V 10×10 mm test specimen 2) |

For thicknesses between 6 – 11.9 mm, sub-size Charpy V-specimens are used. The specifi ed minimum value is then proportional to the cross-sectional area of the test specimen, compared to a full-size specimen (10 x 10 mm). Impact testing according to ISO EN 148 per heat and thickness group. Average of three tests. Single value minimum 70% of specifi ed average. Impact testing is performed on thicknesses ≥ 6 mm.

AR 450 Plates COUNTRY ORIGIN MAKE :

| Brand | Manufacture/Co | Country | HARDNESS RANGE |

| Values for BHN450 | |||

| Abrasion Resistant 450 | Nippon Steel | Sweden | 425-475 |

| QUARD 450 | DUFERCO | Belgium | |

| JFE EVERHARD 400 | JFE STEEL CORPN. | Japan | 400-475 |

| SUMIHARD K450 | SUMITOMO METALS | Japan | |

| ABRAZO 450 | TATA UK LTD. | UK | |

| Abrex 450 | RUUKKI | Finland | 420-500 |

| DILLIDUR 450V | DILLINGER HUTTE | Germany | 420-470 |

| XAR 450 | THYSSEN KRUPP | Germany | 425-477 |

| BRINAR 450 | ILSENBURGER GROBBLECH | Germany | |

| FORA 450 | INDUSTEEL | Belgium | 410-490 |

| NICRODUR 450 | ACRONI | Europe | |

| CREUSABRO 8000 | INDUSTEEL | Belgium | 430-500 |

| WELHARD 450 | NSC/JAPAN | Japan | |

| SWEBOR 450 | SWEBOR STAL | Sweden | |

| BIS Plate 450 | Bisalloy Steels Pty Ltd | Austrelia | 425-475 |

| Rockstar 450 | Essar Steel India Ltd. | India | 425-475 |

| Algo Tuf 450F | Essar Steel India Ltd. | India | 410-477 |

| Abrex 450 | NSSMC | Japan | 410-490 |

| Wearalloy 450 | Ford steel | USA | 444-475 |

| Hardwear 450F | Arcelor Mittal | Luxembourg | 429-495 |

SSSM Group Also Distribute Other Types of AR 450 Namely :

Wear Resistant Steel 450, ABREX 450, SUMIHARD 450, Abrex 450, FORA 450, NICRODUR 450, ABRAZO 450, DUROSTAT 450, DILLIDUR 450V, BRINAR 450, AR 450, HBW 450, HBW 450, 450 BHN, JFE EH400, XAR 450, HB 450, CREUSABRO 8000, SWEBOR 450, SUMIHARD K-450, ABRAZO 450, Abrex 450, DILLIDUR 450V, XAR 450, BRINAR 450, FORA 450, NICRODUR 450, CREUSABRO 8000, WELHARD 450, SWEBOR 450, BIS PLATE 450, ROCKSTAR 450, ALGO TUF 450F, ABREX 450, WEARALLOY 450 Based in Mumbai, India, We, at SSSM Group are driven to achieve the quality that is paramount, thereby confirming that our AR 450 Steel plates are composed of top quality Steel, accompanied by ultra-modern production patterns. Our recognition lies as the quality stockist and exporter located in India, supplying our commendable goods PAN India and exporting them to global markets.

Distributors of custom – built and shipped Abrasion resistant and wear resistant steel plates; we dispatch them under varied styles, with abrasions not contracting their flexible nature.

Abrasion Resistant ABREX 450 Plates We Supply Globally :

We Supply Our Abrasion Resistant 450 Plates to various countries like Turkey, Poland, Zimbabwe, Singapore, Iran, Portugal, Trinidad & Tobago,Tunisia, Sri Lanka, Finland, Nigeria, Gabon, Nigeria, Egypt, Serbia, Angola, United States, New Zealand, Jordan, United Kingdom, Slovakia, France, Iran, South Korea, Malaysia, Ireland, Chile, Austria, Israel, Hungary, Greece, Poland, Sweden, Brazil, Switzerland, Croatia, Estonia, Morocco, Hong Kong, Spain, Taiwan, Russia, Mexico, Afghanistan, Ecuador, Kuwait, Romania, United Arab Emirates, Thailand, Oman, Belgium, Canada, Mongolia, South Africa, Saudi Arabia, Denmark, Italy, Germany, Libya, China, Belarus, Lebanon, Bhutan, Lithuania, Venezuela, Japan, Tibet, Netherlands, Costa Rica, Kenya, Azerbaijan, Australia, Pakistan, Colombia, Indonesia, Philippines, Bahrain, Argentina, Ghana, Namibia, Iraq, Czech Republic, Macau, Ukraine, Algeria, Kazakhstan, Chile, Qatar, Mexico, Vietnam, Yemen, Bangladesh, Puerto Rico, Gambia, India, Peru, Nepal, Bolivia, Norway, Bulgaria.

Abrasion Resistant ABREX 450 Plates We Supply Worldwide :

We Supply Our Abrasion Resistant 450 Plates to various cities like Bengaluru, Brisbane, Sydney, Haryana, New Delhi, Riyadh, Ahmedabad, Rio de Janeiro, Karachi, Cairo, Los Angeles, Surat, Tehran, Istanbul, Kolkata, Caracas, Muscat, Edmonton, London, Thane, Bangkok, Baroda, Algiers, Rajkot, Busan, Kanpur, La Victoria, Santiago, Gurgaon, Petaling Jaya, Ho Chi Minh City, Singapore, Colombo, Kuwait City, Dubai, Ernakulam, Hyderabad, Secunderabad, Ranchi, Manama, Dallas, Montreal, Nashik, Navi Mumbai, Ludhiana, Nagpur, Port-of-Spain, Hong Kong, Houston, Gimhae-si, Jamshedpur, Calgary, Melbourne, Seoul, Pimpri-Chinchwad, Perth, Visakhapatnam, Madrid, Granada, Jaipur, Lahore, Vung Tau, Geoje-si, Aberdeen, Hanoi, Ankara, Jakarta, Coimbatore, Milan, New York, Chiyoda, Sharjah, Kuala Lumpur, Atyrau, Faridabad, Pune, Indore, Ahvaz, Chennai, Bhopal, Al Jubail, Howrah, Toronto, Mexico City, Abu Dhabi, Doha, Dammam, Moscow, Bogota, Vadodara, Noida, Ulsan, Al Khobar, Mumbai, Lagos, Thiruvananthapuram, Chandigarh, Courbevoie, Jeddah.

Application Of Steel Plates Industries

Petrochemical Industries

Marine Industries

Food Processing Industries

Oil & Gas Industries

Packing Of Steel Plates Materials

Plate Size available Ex-Stock of SAILMA 550HI, SAILMA E550, IS 2062 E550

| 1mm | 2mm | 3mm | 4mm | 6mm | 8mm | 10mm | 12mm | 14mm | 16mm | 20mm | 25mm | 30mm | 32mm | 36mm | 40mm | 45mm | 50mm | 63mm | 70mm | 72mm | 75mm | 80mm | 90mm | 100mm | 110mm | 130mm | 150mm | 170mm | 180mm | 200mm | 230mm | 270mm | 300mm |

Makes/Brands Available: SAIL, TATA, JSW, JSPL, Essar, POSCO, Uttam